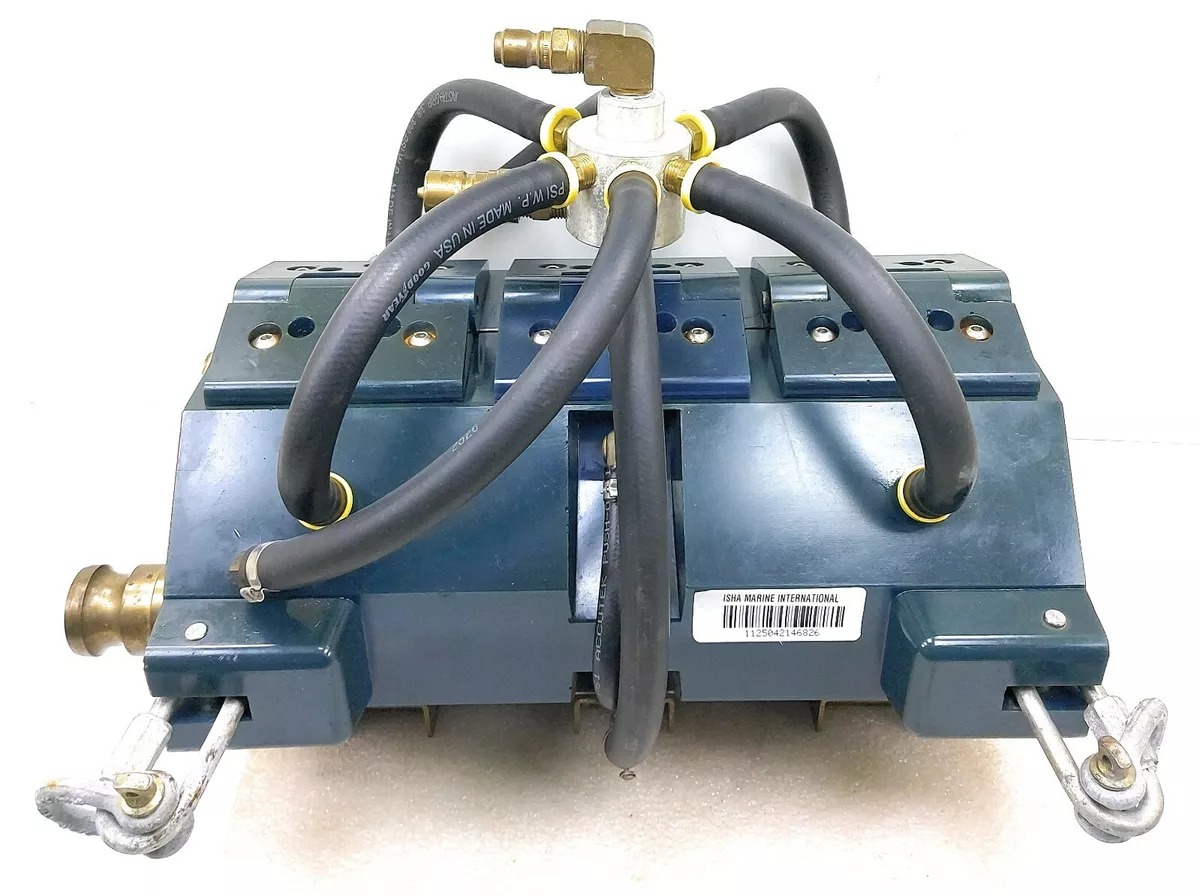

In the nitty-gritty industry of cable maintenance where precision and longevity are paramount, the utilization of advanced tools such as wire rope lubricators, wire cleaners have become essential. These advanced devices are vital to ensure that cables run efficiently and last longer in an array of industries. Rope lubricators and wire cleaners are vital for the maintenance of cables. In this piece, we examine their roles, benefits, and transformative effects on overall efficiency.

Understanding wire Rope Lubricators

Wire rope lubricators are specialized devices designed to apply lubrication to wire ropes systematically. This is essential for preventing corrosion and friction while increasing the durability of the cable. The lubricator ensures that the lubricating agents are evenly distributed along the length of wire ropes, protecting them from wear and tear.

What’s the function of wire cleaners in the maintenance of cables?

Cleaners for wires (also referred to as cable cleaners) are also essential to maintaining the cleanliness and hygiene of cables. They are intended to get rid of debris, contaminants, and liquids that could build up on the cable during various operations. In conditions that are harsh the use of wire cleaning products is necessary to ensure the highest performance. Click here Wire Rope Lubricator

Optimizing Cable Lifespan:

Wire lubricators and cleaners when used in conjunction can greatly extend the lifespan of cables. Wire cleaning equipment and wire rope lubricators work together to apply lubrication and remove dirt. They also shield cables from friction, corrosion and other external factors. This safeguarding of the cable’s strength translates into a longer operational lifespan as well as lower maintenance costs in the long run.

Effectiveness in the application

Wire rope lubricators are developed to be simple to utilize and efficient in their application. They are suitable for many different types and sizes wire ropes, allowing for flexibility in the maintenance of cables. Lubrication that is automated is applied with a consistent procedure, ensuring uniformity and eliminating the risk of uneven coverage.

In challenging environments, adaptability:

Wire rope lubricators and cleaners for wires, are vital in industries where cables must endure harsh conditions, such as those found in construction, drilling or maritime operations. These devices have been designed to be able to withstand extreme conditions. They’re therefore highly reliable devices for maintaining cables.

Cost-Effective maintenance solutions:

A proactive approach to maintenance of your cables which includes the use of cleaning and lubricating the wire rope can be a cost-effective alternative in the long run. The initial investment in these equipments is low compared with the possible costs like repairs and replacements of cables because of poor maintenance.

Conclusion:

Wire rope lubricators as well as cleaners for wires, serve as guardians of the integrity of cables. They provide accuracy, durability and maximum performance in a variety of industries. Cleansing away contaminants as well as the application of lubricants helps in the durability and maintenance of cables. This reduces maintenance and improves operational efficiency. As industries continue to rely on cables to perform their essential tasks using advanced cable maintenance tools like wire rope lubricators and cleaners becomes not just an option but a strategic requirement to ensure long-lasting efficiency and reliability.